The Bourgeoisie, Armalists, Aristocrats. Entrepreneurial Strategies in the Iron Industry in Gemer (1780ÔÇô1881)┬á

DOI: https://doi.org/10.61795/fssr.v25y2023i5.03

Introduction[1]

From a historical perspective, mining, metallurgy, and the iron industry can be consi dered to have been the most significant fields of industry in the 18th and 19th century. Their products were in demand even in the most remote markets. In the territory of present-day Slovakia, the development of the iron industry was facilitated by rich deposits of iron ore and other metals (e.g., copper, cobalt, mercury, nickel, and antimony), extensive forests, water resources, good-quality workforce, and last but not least, the experience and the technological and practical skills gained in the field of mining and metallurgy for centuries.

Contemporaries considered Gemer to be the ÔÇťmain nestÔÇŁ of the iron industry in Hungary, followed by Spi┼í and the environs of Zvolen. It should be noted, however, that, especially after the construction of the railways in 1867, the southern regions of Hungary, mainly Vajdahunyad and Cara┼č-Severin County with the town of Aninab├ínya as its metallurgical center, and also the town of Bra┼čov, all in Transylvania, were gra dually becoming the second most significant iron industrial region, although a much less important one than Gemer (Erd├ęlyi 1846: 169; F├ęnyes 1847: 83; M├│zes 1988: 28ÔÇô29).

This study focuses on the Gemerian context of the iron industry and its enterprises based on rare, yet unexamined, recent sources and, specifically, on the legal predecessors of the Rimamur├ínyÔÇôSalg├│tarj├ín Ironworks, namely the Mur├íny Union, the Rima Coalition, the Gemer Ironworks Association, and the Rimamur├íny Ironworks Association. The management of the Rimamur├ínyÔÇôSalg├│tarj├ín Ironworks, the flagship of the Hungarian iron industry, considered these to have been the direct predecessors of their company with a healthy dose of pride (Gau─Ź├şk 2020). In particular, I deal with prominent organizers, experts, and entrepreneurs active in these companies and briefly portray their careers. At the same time, I trace the most important trends in the development of the iron industry in Hungary, because, through its prism, it is easier to understand the regional context and the strategies of the entrepreneurs and the managers. In this study, I do not devote special attention to the quantification of the iron products nor technological development. Data and contexts pertaining to these can be found in earlier, synthesizing works; Slovak historiographical literature has already dealt especially with the regions of Spi┼í and Zvolen.

The Development of the Iron Industry in Slovakia Until the Late 18th Century

According to some Romantic researchers, the history of the iron industry in Slovakia reaches back to ancient, or even mythical, times.[2] The first written references to an iron industry in the territory of Slovakia date only to the Middle Ages, to the 13th century. Nevertheless, archaeological research has documented its existence a lot earlier, in the 7thÔÇô6th centuries BC (Heckenast 1980: 1).

In the territory of present-day Slovakia, German colonists, Slovaks, and Hungarians played a major role in mining, metallurgy, and the iron industry. It is worth briefly touching upon the ethnicities of the key players in this industry.

In one of his articles, J├│zsef Volny,[3] a product of a SlovakÔÇôGerman family and one of the most knowledgeable experts on Hungarian metallurgy and mining, who held important posts in the structures of the iron industry in Hungary (e.g., he was a member of the board of directors of the influential Orsz├ígos Magyar Iparegyes├╝let [the National Hungarian Industrial Association[4]]) and had an international outlook, discussed the lingual and ethnic situation in the iron industry in Gemer at the turn of the 18th and 19th centuries. He outlines the social composition of the entrepreneurial groups, the positions of bourgeois entrepreneurs, and the later, increased interest of the aristocratic families in the manufacturing of iron products in the region as follows: ÔÇťRoughly until the late 18th century, our iron industry, which had been developing as part of the guild industry, had been managed by wealthy members of the bourgeoisie, who had been in touch with the feudal lords, that is with the Hungarian element, only to the extent that they had been the lessees of their land and water rights and used their extensive forests. This relationship changed in the early 19th century and over the course of that century, when the manufacturers of iron made a fortune, acquired aristocratic privileges, and began to purchase the surrounding forests. On the other hand, the feudal lords began to acquire the hammer mills operating on their properties. That is how it came about that, except for a company or two, the iron industry in Upper Hungary perfectly merged with the feudal lords who held estates, and well-established Hungarian names can be found among the entrepreneurs and those involved in it. We encounter the Bethlens, the Battyh├ínys, the N├ídasdys, the Andr├íssys, the Forg├íches, the Kub├şnyis, the Jeszen├íks, the M├íri├íssys, the Pr├│nays, the F├íys, and other members of the renowned families of our motherland.ÔÇŁ[5]

In the 10thÔÇô13th centuries, there were two major centers of iron production in Hungary (in the northern part of Borsod County and in the western parts of the counties of Vas and Sopron) and several minor, mutually isolated local centers (Heckenast 1980: 1). In the 14th century, after the exploitation of the open-cast ore mines in Vas County and a decrease in the output of the mines in Borsod County, the center of metallurgy and iron production shifted to the regions of Spi┼í and Gemer, and due to their rich reserves of raw materials and suitable sources of water energy, it remained there until the dissolution of the Kingdom of Hungary in 1920. Smelters were established near rich and accessible sources of ores. Smiths made gear and weapons for the royal and the banderial army and agricultural equipment and everyday items for the population (Frisny├ík 1996: 131ÔÇô133).

Hungarian rulers were aware of the importance of mining, metallurgy, and the iron industry for the royal budget and generously supported the free royal mining towns and private individuals by privileges (Izs├│ 2006).[6] Some of the aristocrats of Gemer (including the Bebeks, the Csetnekis, the M├íri├íssys, and the Szont├íghs) ran businesses on their estates, fiercely defending their privileges by which they, logically, got into conflicts with their new competitors, the free bourgeoisie (libertines) from areas including Dob┼íin├í, Jel┼íava, Rev├║ca, and Ro┼ż┼łava, who were also driven by their auri sacra fames (accursed hunger for gold), to paraphrase the above-mentioned J├│zsef Volny. Therefore, they began to specialize in mining ore and other minerals, and to defend their economic interests, they united into mining associations (Mikulik 1880; Mikulik 1885: 4ÔÇô7; Heckenast 1973: 139ÔÇô141).

In a period of boom during the anti-Ottoman battles and the uprisings of the nobi lity, the demand of the armies for offensive and defensive iron weapons increased rapidly, which had a positive impact on the development of entrepreneurship (e.g., the weapon-producing company in Dob┼íin├í). Despite some isolated anti-capitalist features and specializations of guilds (e.g., in the production of arms, including rifles and pointed weapons), the level of metallurgy and iron processing in Slovakia remained low. Better-quality products, components, and accessories of agricultural equipment and machine parts had to be imported from regions lying in present-day Germany or Austria (H. Bal├ízs ÔÇô Makkai 1962: 230).

In the early 18th century, the share of industry, and of the iron industry as part of it, decreased in the Hungarian economy. A new boom of agriculture began due to increased consumption, the availability of land in the southern parts of Hungary after the expulsion of the Turks, the modernization of large estates, investments, and favorable conditions for cereal crops production (Kaposi 2002: 75, 125). The significance of the iron industry began to grow only in the latter half of the 18th century. Western European models of industrialization came into vogue. The philosophy of the economic and fiscal policy of the Viennese Court changed in the spirit of mercantilism. The positive ÔÇťattributesÔÇŁ of an enlightened country, in terms of the general welfare of the imperial population (i.e., an active trade balance and a balanced budget) and efficient taxation that enabled economic growth and led to a militarily powerful country, became the main objectives. As part of the governmentÔÇÖs interventions into economic life, new administrative structures, with motivated, specialized apparatuses, came into being also in the Spi┼í-Gemer mining region. Besides providing guidelines for production, these were to ensure a monopoly for the government (e.g., over copper; Ondru┼íov├í 2013: 161ÔÇô1 62; Lacko 2015: 209ÔÇô230). However, a long conflict over the taxation of mined iron ores (urbura) had been dragging on between the government and the producers. Moreover, despite the centralization efforts and interventions of Joseph II, they did not manage to settle this problem in favor of the government (Heckenast 1986: 1041ÔÇô1042).

In this period, certain changes can be identified in the economic policy of the Habsburgs. Mining officials responded to the deteriorating situation, namely to the increasingly costly copper mining and processing, which had a negative impact on certain towns with rich mining traditions, especially Spi┼í. They began to approve modernization projects of old hammer mills and projects of entrepreneurs, especially from among the aristocracy, of building new hammer mills (the Koh├írys in Pohorel├í, the Andr├íssys in Betliar, blast furnaces in Hronec and Hr├ídok).[7] The key players in metallurgy and in the iron industry in Hungary were the Habsburg government, which acted as the ÔÇťlargest entrepreneurÔÇŁ through its mining chambers, the market-oriented enterprises of the aristocracy, and lastly, in the early 19th century, the first capitalist companies in Gemer.

State-owned ironworks and companies of squires, which were already able to operate efficiently in the domestic market and to at least partially satisfy as much as possible even foreign demand, were of great significance. A brisk iron trade pulsated between the Kingdom of Hungary and the other parts of the empire. Iron was exported from the Lower Hungarian mining region[8] to Moravia and Silesia and from the Upper Hungarian mining region[9] to Galicia, Poland, and even Transylvania. Western Hungarian counties imported iron products form Styria, mainly through Viennese tradesmen. The amount of better-quality iron products (sheet metal, tools, locksmith tools and pro ducts, cast iron, steel) imported from Austria kept increasing (M├ęrei 1951: 113).

Despite the positive progress, the Hungarian iron industry developed less dynamically, especially because of the use of traditional technology and a lack of capital. In amount of raw iron produced, however, Hungary ranked an impressive fourth after Styria, Bohemia, and Carinthia. Although the amount of iron produced in Hungary (excluding Transylvania) in the 1780s, which was around 145,000 Viennese cents (i.e., around 2,589 metric cents), appeared to be insufficient, it was only somewhat lower than the amount produced in the more developed Carinthia (155 Viennese cents).[10] A breakthrough in output increase came about only around the year 1865, when the amount of raw iron reached almost 1 million q [q = quintal] and climbed to 1.4 million q by 1882.[11]

Along the Crooked Paths of Modernization

The ÔÇťcapitalist turnÔÇŁ (i.e., joining forces and creating new organizational forms) was indispensable. It manifested itself prominently in the Slovak territory first in Gemer and already at the turn of the 18th and 19th centuries. The birth of new iron companies was encouraged not only by the already acquired experience and positive developments in the latter half of the 18th century (mainly the spread of blast furnaces from 1760 onwards and the slow disappearance of the so-called Slovak furnaces (slawische/ slowakische Feuer, St├╝ckofen, t├│tkemence, bucakemence),[12] but also by a fortunate constellation (i.e., a favourable economic situation) during the Napoleonic Wars in the beginning of the 19th century.

In the Mur├í┼ł demesne of the Koh├írys, in the latter half of the 18th century, metallurgy was still evolving, and hammer mills were being built in the valley of the Hron river only gradually.[13] The demesne usually leased these out or even sold them to wealthy members of the bourgeoisie from Rev├║ca and Jel┼íava (Barto, Benk├ír, ┼áramko). Some armalists, who were elevated from serfdom in a couple of generationsÔÇÖ time (Czibur, Cz├ękus, G├Âm├Âry, Sturman), had owned hammer mills already in the early 17th century (Heckenast 1986: 1041-1042). The industrial potential of this region is aptly illustrated by the development of the number of smaller ironworks and hammer mills and their output.

Table 1: The Development of the Number of Iron Factories, Smelters, and Furnaces in the Mur├í┼ł Valley (1755ÔÇô1806) (Source: Heckenast 1986: 1043). 14

| Year | Iron Factory | Smelter[14] | Furnace |

| 1755 | 12 | ÔÇô | 18 |

| 1799 | 14 | ÔÇô | 25 |

| 1782 | 14 | ÔÇô | 25 |

| 1806 | 14 | 1 | 25 |

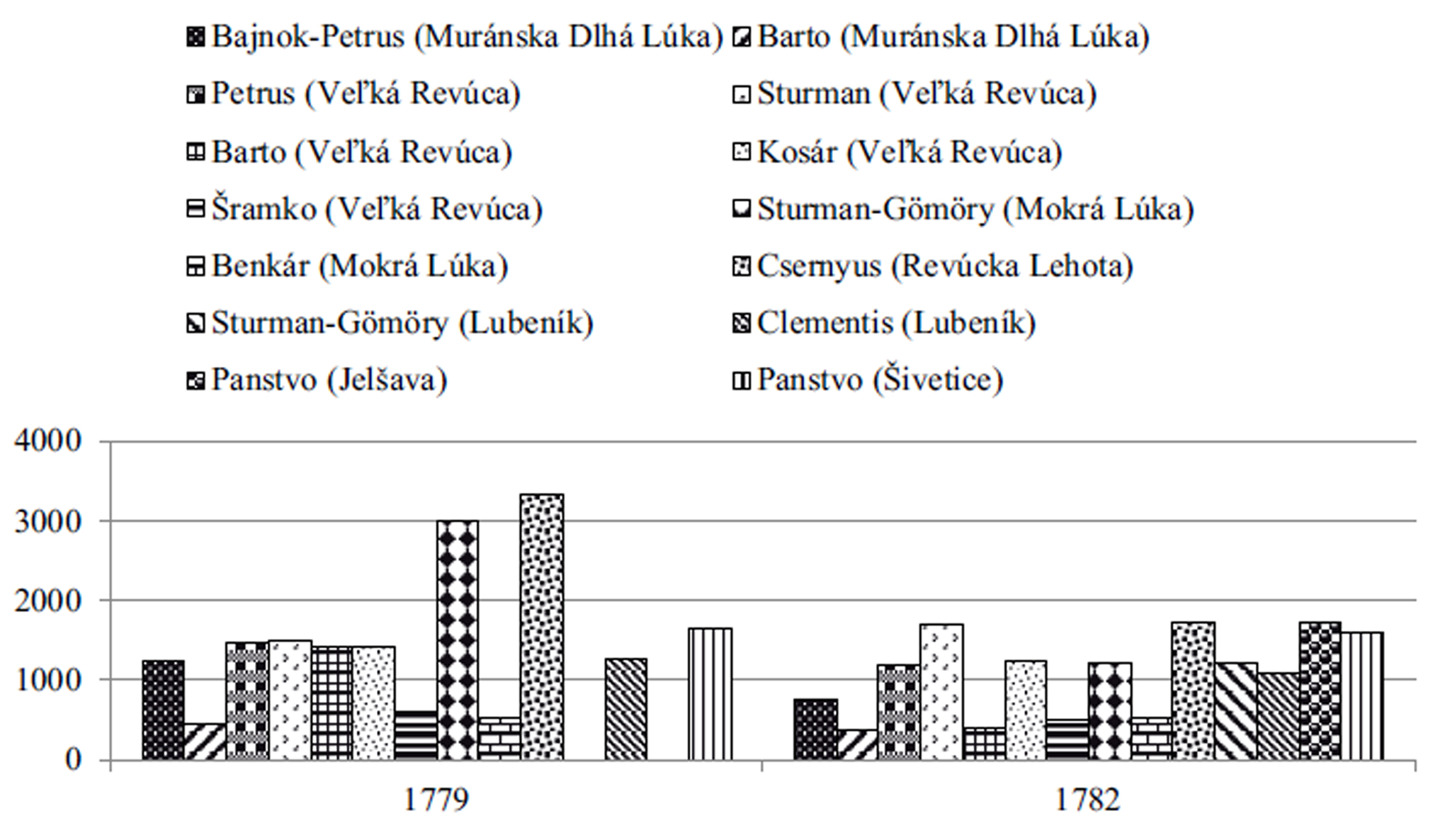

Chart 1: Manufacturing Data of Iron Factories in the Mur├í┼ł Valley (1779ÔÇô1782, Viennese Cent) (Source: Heckenast 1986: 1044).

The data above reveal a quantitative growth of the iron industry in the region and point out a group of ambitious entrepreneurs who specialized in renting or building furnaces in the Koh├írysÔÇÖ demesne. With their purchases, they increased their wealth and asserted their economic interests with increasing self-confidence (e.g., Ondrej ┼áramko, the mayor of Ve─żk├í Rev├║ca). Among the entrepreneur families, we encounter the Sturmanns (whose surname was also stylized as Sturman), who were a prototype of these small, but gradually growing first bourgeois entrepreneurs (i.e., capitalists). Among the iron-producing families of Gemer, it was definitely they who achieved the most rapid social advancement and increase in their assets.

From the early 20th century, in the interwar period (1918 to 1939) still, rumors were being spread about the Swedish roots of the Sturmanns, probably to increase the social prestige of their offspring (Veres 1922: 84; Bar├ít 1935: 30). This Gemerian fami ly allegedly came from a marshal of the Swedish King Gustaf Adolf, an anonymous one, who had fought bravely in the Thirty YearsÔÇÖ War (1618 to 1648) and received great honors and estates for his merits. For reasons unknown, a branch of this unknown warrior settled first in Transylvania and, from there, made its way to Gemer (Tahy 1904: 202).

The truth was a lot simpler, however, and it was in line with the actual life of Gemer. The ancestors of this, most probably German, family of Sturmann came from Rev├║ca. Their names are documented in registers of serfs from the year 1558. Istv├ín, who lived in Mokr├í L├║ka (Vizesr├ęt), was redeemed from serfdom for 280 guilders and acquired armales, along with his sons Andr├ís and Gy├Ârgy, with the title of nobility ├ôzd et Z├ídorh├íza, on March 28, 1699. He was apparently one of the wealthiest serfs of the Koh├írysÔÇÖ demesne, since he owned land and ran a smelter, for which he paid rent to the royal treasury (Sarlay 1933: 35ÔÇô36).[15]

The family had had considerable assets already by the late 17th century, since it had received into custody the praedia of Sirk, Tur─Źok, and ┼Żelezn├şk, all places with significant mines of iron ore, from the Cs├íkys. The Sturmanns acquired these definitively in 1758 (V├ílyi 1799: 414, 538; Heckenast 1986: 1045). Their furnaces accounted for a significant part of the iron production in the Mur├í┼ł Valley. In 1779, they accounted for 25.2%, and in 1782, already 27.1% of the total iron production, overtaking not only their competitors (e.g., the Csernyuses), but even the companies of the Koh├írys.[16] From this family, which was related to the Cz├ękus family of entrepreneurs, the person who achieved the highest social recognition was Martin (Martinus, M├írton) Sturmann, a quite-forgotten figure of the regional history of Gemer. He was the initiator and co-organizer of the first ironworks, a sympathizer with liberal ideas, promoter of arts, and supporter of the Lutheran Church and the needy.[17] Martin Sturmann followed in the footsteps of his father, also called Martin, who had probably laid the foundations for their family enterprise in the iron industry (Heckenast 1986: 1045).

The First Entrepreneurial Companies of the Iron Industry

In the early 19th century, Gemer had a remarkable economic capacity. As much as a half of the iron industry of Hungary was concentrated in that region. Nine smelters and 81 bloomeries, with an annual output of about 200,000 Viennese cents (11.2 million kilograms) operated there. The production facilities ran from spring to autumn. In winter, they shut down for 15 to 20 weeks. The operations were based on feudal estates, where most of the plants were situated. The feudal lords rented out the furnaces and the smelters for urbura (Eisenfron, mining revenues). This type of enterprise changed quickly, however, as closer economic collaboration, the establishment of joint stock companies, the profitability of production facilities, and naturally, achieving the highest possible profit came to the forefront (R├ęti 1977: 12).

The first capitalist company in Gemer was the Societas Massae Chalybeae steelworks, which operated from 1792 to 1798 in the Upper Hron region. Its shareholders had a blast furnace with hammer mills built in the village of Šumiac, but they soon began to face financial problems. They could not achieve their long-term plans of steel production and produced only raw iron. In 1798, the company declared bankruptcy and the production facilities were taken over by the Kohárys (Horváth 1811: 319; Heckenast 1986: 1046).18

A few years later, entrepreneurs in the valleys of the rivers Mur├í┼ł and Rimavica were also mobilized. The Mur├íny Union, with its seat in Bartov├í, was established on May 3, 1808.19 The founding members put into the company as many as 26 mines in ┼Żelezn├şk, the mining field in R├íko┼í, and 14 ironworks in the valley of the Mur├í┼ł river. Its shareholders included members of aristocratic entrepreneur families (Martin and Ondrej Sturmann, Petr├│czy, Ondrej ┼áramko, Bartho, Bart├│ffy, Benk├ír, Engel, Clementis, Cz├ękus), the influential German tradesman and iron entrepreneur and owner of the smelter in Rimavsk├ę Brezovo[18] Georg Ludwig Malvieux,[19] and even the small town of Ve─żk├í Rev├║ca.[20] The business matters were handled by the president of the company was founded by the shareholders Mikl├│s Kir├íly Szathm├íry, ├ëva Cz├ękus, Martin Sturman, J├ínos Kaiser, Gy├Ârgy Samarjay, J├ínos L├ínyi, and Izrael G├Âm├Âry, with the support of the feudal lord Count Ferenc Koh├íry.

the company, Martin Sturmann. Ondrej ┼áramko, considered to have been the first ÔÇťunion director,ÔÇŁ23 apparently also held an important post in the management. Their official books and documents were kept in Slovak and German. Hungarian was additionally introduced into official communication only in 1834.24 The Mur├íny Union established a business in Pest, where its products were sold from the year 1818 onwards by the wholesaler Antal Deron.25

Initially, the industrial complex of the union was able to produce as many as 5,000ÔÇô6,000 Viennese cents of raw iron, 3,000ÔÇô4,000 ingots, and 7,000ÔÇô9,000 Viennese cents of pig iron (R├ęti 1977: 13).26 To increase its production, in 1827 and 1828 the union purchased several forests and water wheels in the valley of the Rimavica river, six hammer mills in the vicinity of Rimavsk├í Kokava, eight refining forges (Frischfeuer) in the valley of the Klinovsk├í Rimavica, and two hammer mills near Klenovec (Lower and Upper Hlinanec) (Koroknai ÔÇô Schlegel 1978: 12).

The iron production of the union progressed rapidly. In the 1830s, it exported raw iron even to V├ştkovice and began to monopolize the interior trade of Hungary. In 1843, it began to build a factory for puddling and rolling in ├ôzd in collaboration with the other iron companies of Gemer. Thanks to the relative expansion of the market, and to the conditions that arose in 1848ÔÇô1849, the Mur├íny Union climbed to the top among private ironworks in Hungary, and even in the field of cast iron production. However, due to the post-revolutionary, negative development of the economy and the narrower market opportunities, a recession hit this company, too. In 1850, for example, as many as 50,000 cents of raw iron remained in its warehouse unsold, leading to a significant decrease in income and the shutdown of some of its hammer mills.27 In 1851, it produced 35,854.5 Viennese cents of raw iron (KoroknaiÔÇôSchlegel 1978: 12).

The other significant iron company, the Rima Coalition (or Rima Ironworks ÔÇô Rimai Vasm┼▒vel┼Ĺ T├írsas├íg ÔÇô as it was usually referred to) was established on May 13, 1810, with its seat in Rimavsk├ę Brezovo in the Malohont region. Its share capital consisted of 128 shares at a nominal value of 2,000 guilders. Its major shareholders included the noblemen Count J├│zsef Luzs├ęnszky, Count Alajos Forg├ícs, members of the Kubinyi family, Martin Sturmann, and the Mur├íny Union (Koroknai 1977: 465). The lawyer of the company was Mikl├│s Ratk├│.[21] Technical matters, the development of iron infrastructure, the increase in the output of its hammer mills and furnaces, and mining and business matters were entrusted to the talented Frigyes Heincz, who held the post of inspector and was a prefect from 1826 (Koroknai 1978: 164). In its Article 12 regarding administrative rules, the ÔÇťCorporate AgendaÔÇŁ of 1812 respected all the commonly spoken languages in the region (i.e., Latin, Slovak, and Hungarian): ÔÇťEvery clerk shall make notes daily about the economy he is handling and shall submit these in time either in Hungarian, or in Latin, or in Slovak, for audit to the respective bureauÔÇŁ (Koroknai 1977: 465).

The industrial and raw material base of the coalition consisted of factories in Rimavsk├ę Brezovo, Likier, and Hn├║┼í┼ą, and iron ore mines in ┼Żelezn├şk, R├íko┼í, and the Rimavica Valley (R├ęti 1977: 14). Right in the year of its establishment, its assets increased significantly by its acquisition of land from Baroness Erzs├ębet Luzs├ęnszky.[22] Over time, the coalition acquired large forest properties in the cadastral areas of the villages Vy┼ín├í Pokoradz, ─îeren─Źany, Selce, Rimavsk├í Kokava, Rimavsk├í Ba┼ła, Likier, and Tisovec. As R├ęti estimated, at its establishment, the Rima Coalition was able to produce raw iron amounting to 7,000ÔÇô8,000 Viennese cents and a significant amount of malleable iron of 4,000ÔÇô5,000 Viennese cents. In the first two decades of the 19th century, the company exploded in the Hungarian market and significantly increased its production capacity. It established two new hammer mills and blast furnaces (in R├ízto─Źno, Likier, and Rimovce). It was not a chance that the first iron cartel agreement on the prices of iron products in Hungary, which was basically a market regulation, was reached between this coalition and the KoburgsÔÇÖ ironworks. However, the early 1830s brought not only a cholera epidemic and a social crisis, but also financial distress. The coalition acquired a loan with a significantly higher interest rate (research has not focused on concrete providers of such capital yet), and it could reimburse it only with a significant delay and only thanks to the new, more favorable situation and an increase in production. In 1839, for example, it increased the amount of malleable iron to 13,200 Viennese cents (R├ęti 1977: 15).

R├ęti formulated a thesis that the Rima Coalition began to gradually lag behind the Mur├íny Union. As he noted, the Rima Coalition had produced the same amount of raw iron as the Mur├íny Union in 1841 (10% each), but a few years later it fell behind its regional competitor and was unable to increase production, while the union doubled its own production and overtook even the KoburgsÔÇÖ ironworks. R├ętiÔÇÖs estimate is based on the earlier research of Gyula M├ęrei, but he did not quantify the extent of the decline of the production of the company in Rimavsk├ę Brezovo. According to the Austrian mining statistics of 1839, it is noteworthy that iron producing companies in Gemer were able to produce more raw iron together (the Mur├íny Union 20,155 Viennese cents and the Rima Coalition 28,260 Viennese cents) than the KoburgsÔÇÖ company (36,800 Viennese cents). In the field of cast iron production, however, both the union and the coalition lagged significantly behind the companies of not only the Koburgs, but also of the Andr├íssys (R├ęti 1977: 17).[23]

The shareholders of the coalition were aware of the decline and of their technolo gical backwardness and problems with domestic consumption; therefore they contacted Tivadar Rombauer,[24] a native of Levo─Źa, who was already a recognized expert at that time, and offered him the post of company director (Lehoczky 1965: 82). Probably at the initiative of Rombauer and the other managers of the coalition and the union, the most significant meeting of the iron producing companies in Gemer took place under the leadership of Count Gy├Ârgy Andr├íssy.[25] They met on January 23, 1843, in the picturesque mansion of the Andr├íssys in Kr├ísnohorsk├í Dlh├í L├║ka.[26]

This was essentially the first time that the situation and the alternatives in the development of the Hungarian iron industry were discussed systematically. The partici pants identified the basic problems (i.e., the limitations of an underdeveloped iron market, the poor transport infrastructure, the obstacles in the form of export duties, and the overall backwardness of the country). They initiated the abolition of the customs border between Austria and Hungary, and they called for the protection of the export of iron products from the Habsburg Monarchy. They pointed out the necessity of a rational construction of a railway network between Hungary and foreign lands, as well as between the developing Pest and the most important regions of the iron industry. The participants considered it important to financially support industrial entrepreneurship by establishing a bank of superregional significance in Ko┼íice. They initiated the development of secondary mining schools and universities and the exchange of experience between stakeholders in the iron industry (R├ęti 1977: 18). These progressive proposals and recommendations reflected the liberal ideas of Count Gy├Ârgy Andr├íssy and the knowledge he gained during his travels in England, France, and the German lands from 1832 to 1834. As a close collaborator of Count Istv├ín Sz├ęchenyi, he advocated for the modernization of Hungary (Brigov├ícz 2008: 167ÔÇô188). On the other hand, the presented proposals also reveal the Andr├íssysÔÇÖ strong lobbying motives and their long efforts to uplift and further develop the iron industry and the road network in Gemer and, thereby, also their family mines, smelters, and factories.[27]

The meeting in Kr├ísnohorsk├í Dln├í L├║ka became a crucial one for the establishment of Rimamur├ínyÔÇôSalg├│tarj├ín Ironworks. That is where the idea to establish an iron factory in ├ôzd in Borsod County, which would focus its production on a voluminous amount of railway tracks for the construction of a countrywide railway network in Hungary, was formulated.

On October 14, 1844, in Rimavsk├í Sobota, the Mur├íny Union, the Rima Coalition, and the aristocrat entrepreneurs of the iron industry, including the most active Andr├íssys, approved a plan to establish an iron factory in ├ôzd and create a new organizational structure of the Gemer Ironworks Association (G├Âm├Âri Vasm┼▒vel┼Ĺ Egyes├╝let).[28] Allegedly, the first person to have publicly pronounced this was a delegate of the Mur├íny Union, J├ínos Czibur (├ôv├íri 1967a: 440). The company started its activities officially on May 17, 1845 (Szigetv├íri 1962: 152).36

The place of the new plant, however, became the subject of an extensive debate.[29]Already back in 1843, Count Gy├Ârgy Andr├íssy preferred the cadastral area of the village of Saj├│p├╝sp├Âki, while others were for several localities in the valley of the Slan├í (Saj├│) river. At their meeting in Rimavsk├í Sobota, a proposal for a further unspecified place at the northern foothills of the M├ítra mountain range also came up. The Rima Coalition suggested the valley near the village of Saj├│v├írkony in the vicinity of ├ôzd. Ultimately, the stakeholders agreed on ├ôzd, where they purchased a property of an area of 20 cadastral jutros. The construction of the factory began on April 20, 1845. The machinery was provided by the Lutz & Dobs machine factory from Brno. Twenty to 25 specialists and 80ÔÇô100 day laborers worked on erecting the structures. The management of the Gemer Ironworks Association consisted of five members. Its president was P├íl Kir├íly Szathm├íry, the director of the Rima Coalition.[30] Technical work was supervised by the above-mentioned Tivadar Rombauer. The Mur├íny Union was represented by the engineer of Gemer County, J├ínos Czibur, and a mining expert, the metallurgical engineer J├│zsef Benk├ír (R├ęti 1977: 18ÔÇô19).[31] The technical director was an Austrian engineer, Kajet├ín Fohn, who supervised the construction and was responsible for the acquisition of machinery for the production of raw and malleable iron and components.[32]

The company had a share capital of 250,000 guilders and issued 25 shares for its acquisition (i.e., each share was worth 10,000 guilders). Of the shares, 40% was owned by the Mur├íny Union and the Rima Coalition (owning five shares each). Count K├íroly Andr├íssy and the banker M├│ric Ullmann Szit├ínyi owned two shares each; P├íl Kir├íly Szatm├íry, the squires S├ímuel Drask├│czy[33] and Ferenc Rag├ílyi, the towns of Rimavsk├í Sobota and Ve─żk├í Rev├║ca, the engineers of the company (Rombauer, Fohn, and Gotthard), and small local entrepreneurs owned one share each. The group of the small local entrepreneurs included not only prominent officials and experts in the iron companies of Gemer (the drafter of the foundry in Hn├║┼í┼ą, Frigyes Heincz[34] of the Rima Coalition and J├ínos Czibur of the Mur├íny Union), but also an iron trader (P├íl Juren├ík from Pest) (R├ęti 1977: 19; Jenei 1980: 52; Szigetv├íri 1962: 152).[35]

The ironworks (rolling mill) in ├ôzd was designed to produce railway tracks, sheet metal, and steel of various type in a quantity of about 100,000 Viennese cents. It was equipped for this purpose with 10 puddling furnaces and steam engines with 90 horsepower, which powered a lathe, sheet metal cutters, and pumps. To ensure production, contracts to supply raw iron were reached with the Mur├íny Union, the Rima Coalition, and the companies of the Andr├íssys. The company acquired the right to mine lignite in the vicinity of ├ôzd, with which it was experimenting successfully. A safe and fast transportation of the products required transport networks to be built, so a bridge was erected near the village of Saj├│p├╝sp├Âki, and the road between ├ôzd and B├ínr├ęve was renovated (Szigetv├íri 1962: 152; R├ęti 1977: 19). The technological significance of the ironworks in ├ôzd for Hungarian railways was immense as, until then, the country had had to rely on Austrian and Czech lands (Pr├Ąval in Carinthia and V├ştkovice) for providing rolled iron products (├ôv├íri 1967a: 437). However, the envisaged lucrative deal with the Central Hungarian Railways (Magyar K├Âzponti Vas├║tt├írsas├íg, Ungarische CentralEisenbahn) was not struck, and in 1847, the Gemer Ironworks Association had to resort to increasing its capital to 350,000 guilders to maintain its liquidity (├ôv├íri 1967b: 489).[36]

Nevertheless, the management and the shareholders were optimistic about the future. Work was progressing well, although the industrial complex was still unfinished. What they could not have foreseen, however, were the events of 1848 and 1849, specifically the state of war, the disruption of the economy, and the subsequent crisis with a major impact on the development of the iron industry in Gemer.

In the Service of the War Economy

With respect to private mining and iron industry, noteworthy, and even progressive, changes took place in the spring of 1848. In May, the Hungarian government, led by Lajos Kossuth, began to form a new organizational structure for mining, metallurgy, and iron production in Hungary and tried to reduce its dependence on Vienna. At their negotiations in Pest, the members of the parliament and the delegates of mines and iron companies repeatedly discussed a new form of Hungarian economy, the harmonization of the interests of the state and of the individuals, as well as the need for a new mining law and the improvement of the social status of miners (partly to eliminate social and ethnic unrest). The representatives of the Rima Coalition (Vilmos Kubinyi, Tivadar Rombauer, and Mikl├│s Ratk├│) and the Mur├íny Union (J├│zsef Benk├ír) also participated in these negotiations. All of them actively worked in committees that dealt with specific problems of individual production areas (Sashegyi 1969: 323ÔÇô352).

The idea to unite forces and create more efficient forms of entrepreneurship in the iron industry was also revived. It came up on May 10, 1848, when the representatives of the Mur├íny Union initiated their fusion with the Rima Coalition, but the shareholders of the coalition rejected it (R├ęti 1977: 20ÔÇô21). The position and the business strategies of the Mur├íny Union and the Rima Coalition changed drastically in the autumn of 1848, when the definitive rift between imperial Vienna and revolutionary Pest escalated into armed conflict. Iron-producing companies and enterprises specializing in the production of iron components became crucial elements of the emerging Hungarian arms industry, which were to ensure the self-sufficiency of the Hungarian revolutionary army and provide an arsenal especially for artillery and infantry. On the other hand, the interventions of KossuthÔÇÖs government and the forceful enforcement of state interests met with passivity, and sometimes even unwillingness, from private iron-producing companies, which regarded these regulations and intentions as harmful. The reason was that the rapid reprofiling of iron companies required not only the modification of their machinery and new investments, but to a certain extent, even retraining their workforce and employing new specialists. Some companies saw in the purchase orders and loans of the revolutionary government an escape from their crisis and an opportunity to increase their liquidity and, in a very short time, they became subsuppliers of the National Arms Factory (Orsz├ígos Fegyvergy├ír) in Pest. Some entrepreneurs were more cautious and waited. However, especially after September 1848, Minister of Defence L├íz├ír M├ęsz├íros stepped in drastically and forced them to actively participate in the armament policy of the Hungarian government. L├íz├ír went as far as threatening unwilling entrepreneurs with ÔÇťnationalizingÔÇŁ (i.e. confiscating) their property.

In the case of the Rima Coalition, it was Lajos Kossuth himself who intervened. We do not know the details of the attitude of the management and the shareholders, but in a letter dated November 20, 1848, Kossuth urged them impatiently to produce cannonballs and grenades of the required quantity. Three days later, a contract was signed by a delegate of the coalition, Vilmos Kub├şnyi, and Minister of Defence L├íz├ír M├ęsz├íros. According to this contract, the coalition was liable to supply 10,000 grenades, weighing seven Viennese Pfunds, for the Hungarian revolutionary army and deliver them to Pest by March 19, 1849. Production took place in Hn├║┼í┼ąa. After inspection, the ministry paid 12 guilders for 100 Viennese Pfunds of good ammunition and three guilders for nonfunctional ones. The coalition had to transport these unusable cannonballs at its own cost to the premises of the National Arms Factory (Szigetv├íri 1962: 154).

The Rima Coalition produced 20,568 grenades in total, of which it delivered only 17,314. Due to the retreat of the Hungarian revolutionary forces, the rest were stored in a mine near the village of Sirk, from where they were later transported to Málinec to be smelted. However, the imperial forces confiscated them, along with their molds (Szigetvári 1962: 157).

On the surface, the Gemer Ironworks Association took a proactive part in arms production. It contacted Gerhard Heinrich Knutzen,[37] an engineer of Dutch origin in Pest, in the matter of rifle production for the infantry. A contract was signed on July 12, 1848. Knutzen was to study rifle production in England, Belgium, and France, and acquire machinery for the production on behalf of the company. However, due to the state of war and the closure of the borders of the Habsburg Monarchy, this project did not unfold as anticipated (Szigetvári 1962: 158).

In the autumn of 1848, the Hungarian government returned ÔÇô that is to say, in an escalated situation, it had no other choice but to return ÔÇô to its original idea of producing rifles in Hungary. On November 21, 1848, it entered into a contract with Knutzen and provided a loan of 60,000 guilders, at 4% interest, to the Gemer Ironworks Association and undertook to provide components so that the rolling mill in ├ôzd could commence production. However, the company did not proceed well with rifle production, whether due to the worsening political and economic conditions or due to the threat of invasion by Austrian troops. An unexpected change occurred in early January 1849, when the Hungarian government fled Pest away from the advancing Austrian troops. Tivadar Rombauer, who was liable for the evacuation of the National Arms Factory, moved the lathes, the drills, and the other machines for rifle production to ├ôzd, where production started immediately under the supervision of the state. Due to alleged sabotage (non-repaired machines, no coal, disorganization of the production), however, rifle production progressed slowly. By June 1849, only three 350 Viennese Pfunds of sheet metal had been processed for rifles. The machinery of the National Arms Factory was ultimately transported back to Pest (Szigetv├íri 1962: 158ÔÇô165; ├ôv├íri 1967b: 485).

On June 21, 1849, without scruples, the Gemer Ironworks Association quantified its financial demands against the state. It demanded 36,932 guilders for the use of machines, for unfulfilled contractual obligations, for laborersÔÇÖ wages, and for the produced iron products, and it appears to have received this amount (Szigetv├íri 1962: 166).

In the summer of 1849, iron production in Gemer stopped completely. The ironworks in Ózd was occupied by Slovak voluntary corps led by Major Henrik Lewartovski. The premises were meticulously burgled and some of the machines, technical equipment, and 520 Viennese Pfunds of rolled iron were taken away (Óvári 1967b: 485).

The Quest for New Paths

After the revolution, iron-producing companies faced a number of problems, especially financial and economic ones. The completion of major technological investments in iron and steel production, which had begun before 1848, became a priority. Domestic capital was inadequate. Moreover, major Hungarian commercial banks, mainly the ones in Pest, had not yet specialized in targeted lending to industries. In an economically subverted country, foreign capital was being cautious and some firms, for example the Gemer Ironworks Association, struggled with financial difficulties. The departure of qualified foreign experts, which began already in March 1848, and the shortage of the part of the workforce that had joined the Hungarian revolutionary army and had been persecuted after the Surrender at Világos, worsened the situation further (Vass 1977: 9).

The management and the shareholders of the Murány Union, the Rima Coalition, and the Gemer Ironworks Association were aware of the problems that hindered progress. Austrian iron companies were increasingly dominating the Hungarian market, and Hungarian iron companies, not only not proceeding jointly, but sometimes even going against each other, could not seriously compete. On the other hand, they could capitalize on the experience that they had gained with the establishment of the ironworks and rolling mill in Ózd. To join forces was therefore not only logical, but even indispensable.

Their fusion was urged especially by the Gemer Ironworks Association, which was in financial distress due to the worthless Kossuthian currency and an inadequate amount of goods in stock and was in danger of bankruptcy. The reason for the accumulation of the banknotes of the revolutionary Hungarian government was that Gemer, whose territory had not yet been entered by Austrian and Russian troops in the summer of 1849┬á became an ÔÇťislandÔÇŁ for this money. A ÔÇťregional bubbleÔÇŁ was essentially created, which led to a decline of all the economic sectors. An influx of worthless ÔÇťKossuthian banknotesÔÇŁ began from the neighboring counties, and the population tried to get rid of them as fast as possible (Steier 1937: 588; ├ôv├íri 1967b: 485ÔÇô486).

In this difficult situation, when production facilities had not been operating for almost two years, what would have been lifesaving for the management of the Gemer Ironworks Association would have been a large loan (they needed capital in the amount of 60,000 guilders) or foreign investment. Two of its delegates, the squire Gyula Drask├│czy and J├ínos Czibur, were therefore commissioned to gain financial aid. After their negotiations in Pest and Vienna failed, they tried their luck in Carinthia and Styria, also in vain. Ultimately, they managed to attract a Viennese iron-producing company, Lachner & Heinrich, which provided a loan of 21,000 guilders and even guaranteed the sale of their products. Thanks to this modest loan, shareholdersÔÇÖ donations, and the involvement of an expert, the Austrian engineer Valentin Gotthard, production resumed in ├ôzd in early 1851. Laborers were recruited from the close vicinity, such as from Betliar. However, despite the initial, although only partial, success, the collaboration with the Viennese company became problematic and the crisis of the company deepened further (├ôv├íri 1967b: 485ÔÇô486).

In 1852, on the initiative of the Rima Coalition, negotiations began over the establishment of a new company. The Rimamur├íny Ironworks Association (Rimamu r├ínyv├Âlgyi Vasm┼▒ Egyes├╝let) was established on July 6, 1852, with the fusion of three enterprises ÔÇô the union, the coalition, and the mining company ÔÇô by joining their production capacities and funds. The focus of iron production in the wider region definitively shifted to ├ôzd. A share capital of 55% was raised by aristocrats, 25% by small entrepreneurs (i.e., forgers), 15% by the towns of Rimavsk├í Sobota and Ve─żk├í Rev├║ca, and 5% by traders.[38] Guszt├ív F├íy[39] became the president of the Rimamur├íny Ironworks Association, and the experienced J├│zsef Benk├ír was appointed as its chief inspector, which was essentially its director, and he held this post until his retirement in 1856. He was succeeded by the above-mentioned, agile J├│zsef Volny, whose leadership was considered by the contemporaneous press as years of boom for the ironworks in ├ôzd.

Under the directorship of Benkár, new investments were implemented, such as the construction of steam hammers and steam boilers and residential buildings for the laborers. However, the proposed comprehensive modernization, thanks to which the output of the ironworks in Ózd would have achieved iron production in the amount of 30,000 Viennese Pfunds, did not take place due to the cautiousness of the shareholders. Progress was more systematic under Volny, who was more successful at convincing the shareholders to fund new projects (a rolling mill, soldering furnaces, cutters). In 1858, he managed to achieve an old goal: their new workshop began to produce railway tracks. Another achievement of his was the establishment of the ironworks in Borsodnádasd in 1864. However, the Rimamurány Ironworks Association also inherited a heavy burden from the Gemer Ironworks Association, the scandal of the so-called Hungarian money. From 1850, the Viennese government demanded that it pay back the 60,000-guilder grant provided to the people of Gemer by the Hungarian revolutionary government. A lawsuit followed, which dragged on until as late as 1863. In that year, the company had to surrender and pay a smaller amount, 36,000, which it nevertheless missed badly in its subsequent years.

The 1850s brought other negative developments in the iron industry, too. The iron producing companies of the monarchy could not compete with English producers of railway tracks, so they were forced to change their manufacturing profile and redirect it to steel bar production. This change led to overproduction and, consequently, to a long crisis in the Hungarian iron industry (Óvári 1967b: 486).

Conclusion ÔÇô The Vision of the Centralization of the Iron Industry of Hungary

ÔÇťIn the future, our iron industry can develop only in the current direction and only on the present-day basis, but for it to be able to meet the justified demand of the consumers for cheap iron, it must adjust; on the other hand, in the case of the liberalization of the internal market, it is necessary for it to resist the discounted products of foreign competition; the scattered small companies must unite into larger units.ÔÇŁ (Volny 2003: 41) This is how J├│zsef Volny formulated his vision based on his long experience and contemporaneous trends. His words also confirm the progressive 19th-century idea that the socioeconomic modernization of Hungary, the upliftment of backward areas, and the civilizational progress of the population can be ensured not only by the state, but also by entrepreneurial groups that had large raw material reserves and capital and could attract experts with adequate technological and managerial experience. Of course, the state had to respect the principles of, sometimes overly idealized, laissez-faire and bear in mind the tried and tested principles of supply and demand to create suitable laws and an overall ÔÇťhealthy atmosphereÔÇŁ for entrepreneurship in the country.

In VolnyÔÇÖs concept, the economic elite was assigned a prominent position at the regional level. With their close collaboration, the aristocracy, the wealthy middle nobility, and the corporations could establish entrepreneurship in iron production, mining, and metallurgy, and make it more efficient. Their activities could be of a major significance for the national economy and earn recognition and facilitate the social development of the region. He also investigated the most important political, financial, and transport possibilities of the development of mining and metallurgy, not only in the region of Gemer, but also in comparison with the other regions of Upper Hungary. Although unconsciously, but in the depths of his deductions, he did identify four longintertwined phenomena: the attitude of the Austrian/Hungarian state to iron-producing companies (industrial policy and its metamorphoses), the application of the latest technological know-how from abroad, the activities of entrepreneurs, especially from among the aristocracy, and the centralizing process of the iron-producing companies.

According to some other experts, the self-sufficiency of Hungarian iron companies could have been realistically achieved, to a certain degree, by increasing their capacities, but they still would have had to have relied on the import of steel and iron products from Austria (Kerpely 1884: 29). Technological innovations began to be applied, including the transition from water sources to steam engines, a more intense use of coke, and the planning of more modern smelters. Finally, an influx of foreign, especially Austrian, capital and the arrival of experts from Czechia, Austria, and Germany could also be observed. Nevertheless, the foundations for the new development of the iron industry in Hungary and Slovakia were laid by the experience of the iron entrepreneurs of the first half of the 19th century.

Literature

Bar├ít, Endre 1935. A magyar n┼Ĺnevel├ęs apostola. In Ujs├íg, 8 December 1935, Vol. 11, No. 280, 30.

Berend, T. Iv├ín ÔÇô Szuhay, Mikl├│s 1975. A t┼Ĺk├ęs gazdas├íg t├Ârt├ęnete Magyarorsz├ígon 1848ÔÇô 1944. Budapest, Kossuth K├Ânyvkiad├│; K├Âzgazdas├ígi ├ęs Jogi K├Ânyvkiad├│.

Boros, G├íbor. A di├│sgy┼Ĺri koh├íszat Csavar- ├ęs H├║zott├íru Gy├ír├ínak t├Ârt├ęnete 1770ÔÇô2007.

Miskolc, Pfliegler J.┬á Ferenc Eml├ęk├ęre a Borsod-Aba├║j-Zempl├ęn Megyei Lev├ęlt├ír├ęrt Alap├ştv├íny, 2007.

Borovszky, S├ímuel (ed.) 1903. G├Âm├Âr-Kishont v├írmegye. Budapest, Apollo Irodalmi T├írsas├íg.

Brigov├ícz, L├íszl├│ 2008. Egy tanulm├íny ├ęrt├ęk┼▒ napl├│ ÔÇô Andr├íssy Gy├Ârgy angliai utaz├ísa. In T├Ârt├ęneti Tanulm├ínyok, Vol. XVI, Acta Universitatis Debreceniensis, Series Historica LX,┬á Debrecen, Debreceni Egyetem, 167ÔÇô188.

Eisele, Guszt├ív 1907. G├Âm├Âr ├ęs Kishont t├Ârv├ęnyesen egyes├╝lt v├írmegy├ęnek b├íny├íszati monografi├íja. Vol. 1. Selmeczb├ínya, Kiadja az Orsz├ígos Magyar B├íny├íszati ├ęs Koh├íszati Egyes├╝let Borsod-G├Âm├Âri Oszt├ílya.

Erd├ęlyi, J├ínos 1846. Nemzeti iparunk. Pest, Heckenast Guszt├ívn├íl.

F├ęnyes, Elek 1847. Magyarorsz├íg le├şr├ísa. Vol. 1. Pest, Nyomatott Beimeln├ęl.

Fricz-Moln├ír, P├ęter 2019. Kir├íly Ir├ęn csal├ídt├Ârt├ęneti visszaeml├ękez├ęse. Turul, 2019, Volume 92, Issue 4, 175ÔÇô187.

Frisny├ík, S├índor 1996. Az ├ürp├íd-kori Magyarorsz├íg gazdas├ígf├Âldrajza. F├Âldrajzi K├Âzlem├ęnyek, 1996, Volume 70, Issue 2ÔÇô3, 119ÔÇô136.

Gau─Ź├şk, ┼átefan 2020. Podnik v os├şdlach ┼ít├ítu. Podnikate─żsk├ę elity na pr├şklade Rimamur├ínsko┼íalg├│tarj├ínskej ┼żeleziarskej spolo─Źnosti. Bratislava, Historick├Ż ├║stav SAV; Veda.

- Bal├ízs, ├ëva ÔÇô Makkai, L├íszl├│ (eds.) 1962. Magyarorsz├íg t├Ârt├ęnete 1526ÔÇô1790. Budapest, Tank├Ânyvkiad├│.

Heckenast, Guszt├ív 1958. A mur├ínyv├Âlgyi vash├ímoros c├ęh szab├ílyzatai (1585 ÔÇô 1713 ÔÇô 1755). T├Ârt├ęnelmi Szemle, 1958, Volume 1, Issue 3ÔÇô4, 430ÔÇô447.

Heckenast, Guszt├ív 1961. A feud├íliskori magyarorsz├ígi vaskoh├íszat historiogr├ífi├íja. T├Ârt├ęnelmi Szemle, Volume 4, Issue 1, 1961, 123ÔÇô129.

Heckenast, Guszt├ív 1973. ┼Żeleziarsky priemysel Ro┼ż┼łavy na za─Źiatku 18. storo─Źia. Obzor Gemera, 1973, Volume 4, 139ÔÇô141.

Heckenast, Guszt├ív 1980. A vash├ímor elterjed├ęse Magyarorsz├ígon (14ÔÇô15. sz├ízad). T├Ârt├ęnelmi Szemle, 1980, Volume 23, Issue 1, 1ÔÇô29.

Heckenast, Guszt├ív 1985. A vaskoh├íszat technikai szintje Magyarorsz├ígon a 16ÔÇô18. sz├ízadban. Sz├ízadok, 1985, Volume 119, Issue 4, 917ÔÇô940.

Heckenast, Guszt├ív 1986. Magyarorsz├íg vastermel├ęse II. J├│zsef kor├íban. Sz├ízadok, 1986, Volume 120, Issue 5ÔÇô6, 1040ÔÇô1094.

Horv├íth, Mih├íly 1811. Az ipar ├ęs keresked├ęs Magyarorsz├ígban a h├írom ut├│ls├│ sz├ízad alatt. Buda, A Magyar Kir. Egyetem bet┼▒ivel.

Izs├│, Istv├ín 2006. Szemelv├ęnyek a k├Âz├ępkori montanisztika magyarorsz├ígi t├Ârt├ęnet├ęnek ├şrott forr├ísaib├│l (1000ÔÇô1526). Rudab├ínya, ├ërc- ├ęs ├üsv├ínyb├íny├íszati M├║zeum Alap├ştv├íny.

Jenei, K├íroly 1980. Az alap├şt├ís ├ęs ├╝zembe helyez├ęs. In: Berend, T. Iv├ín (ed.). Az ├ôzdi Koh├íszati ├ťzemek t├Ârt├ęnete. ├ôzd, ├ôzdi Koh├íszati ├ťzemek.

Kaposi, Zolt├ín 2002. Magyarorsz├íg gazdas├ígt├Ârt├ęnete 1700ÔÇô2000. Budapest; P├ęcs, Dial├│g Campus Kiad├│.

Kerpely, Antal 1884. A magyar vasipar j├Âv┼Ĺje (a legk├Âzelebbi t├şz ├ęvben). Budapest, A M. T. Akad├ęmia k├Ânyvkiad├│-hivatala.

Koroknai, ├ükos 1977. Egy feud├íliskori r├ęszv├ęnyt├írsas├íg (Rimai Coalitio) szervezete ├ęs m┼▒k├Âd├ęse. Lev├ęlt├íri Szemle, 1977, Volume 27, Issue 3, p. 457ÔÇô487.

Koroknai, ├ükos 1978. Heincz Frigyes, a Rimai Coaliti├│ kiemelked┼Ĺ m┼▒szaki vezet┼Ĺje. M┼▒szaki ├ęrtelmis├ęgi ├ęlet├║t a XIX. sz├ízad elej├ęn. B├íny├íszati ├ęs Koh├íszati lapok. Koh├íszat, 1978, Volume 111, Issue 4, 163ÔÇô171.

Koroknai, ├ükos ÔÇô Schlegel, Oszk├ír 1978. A Rimamur├íny-Salg├│tarj├íni Vasm┼▒ R├ęszv├ęnyt├írsas├íg t├Ârt├ęnete 1808ÔÇô1918. A v├íllalat gazdas├ígi lev├ęlt├íra alapj├ín. Budapest, V├ŹZDOK.

Lacko, Miroslav 2015. ┼át├ítne financie habsburskej monarchie a uhorsk├í me─Ć v obdob├ş vojny o rak├║ske dedi─Źstvo. Na ceste k nov├Żm kontraktom. Historick├Ż ─Źasopis, 2015, Volume 63, Issue 2, 209ÔÇô230.

Lehoczky, Alfr├ęd 1965. Rombauer Tivadar ├ęs a borsodi ipar. Borsodi Szemle, 1965, Volume 9, Issue 2, 82ÔÇô84.

M├ęrei, Gyula 1951. Magyar iparfejl┼Ĺd├ęs 1790ÔÇô1848. Budapest, K├Âzoktat├ís├╝gyi Kiad├│v├íllalat.

Mikulik, J├│zsef 1880. A b├ínya- ├ęs vasipar t├Ârt├ęnete Dobsin├ín. Budapest, Az Athenaeum R. t├írsulat k├Ânyvnyomd├íja.

Mikulik, J├│zsef 1885. Magyar kisv├írosi ├ęlet 1526ÔÇô1715. Rozsny├│, Kov├ícs Mih├íly k├Ânyvnyomd├íja.

M├│zes, Mih├íly 1988. Az erd├ęlyi-b├ín├íti nagyipari fejl┼Ĺd├ęs f┼Ĺbb bekapcsol├│d├ísi szektorai (1867ÔÇô 80). Magyar T├Ârt├ęneti Tanulm├ínyok, 1988, Vol. 21, Debrecen, KLTE, 27ÔÇô40.

Ondru┼íov├í, Eva 2013. Kameralistika v te├│rii a praxi: pr├şpad Habsburskej monarchie. Kov├í─Ź, Du┼ían et al. Sondy do slovensk├Żch dej├şn v dlhom 19. storo─Ź├ş. Bratislava, Historick├Ż ├║stav SAV, 158ÔÇô172.

├ôv├íri, Antal 1967a. Az ├│zdi vasm┼▒ alap├şt├ís├ínak els┼Ĺ ├╝zem├ęveinek v├ízlatos t├Ârt├ęnete I. Koh├íszati Lapok, 1967, Volume 100, Issue 10, 437ÔÇô442.

├ôv├íri, Antal 1967b. Az ├│zdi vasm┼▒ alap├şt├ís├ínak els┼Ĺ ├╝zem├ęveinek v├ízlatos t├Ârt├ęnete II. Koh├íszati Lapok, 1967, Volume 100, Issue 11, 485ÔÇô491.

Paul├şnyi, ├ükos 1963. A szlov├íkiai bucakemenc├ęk (├║n. t├│tkemenc├ęk) ├ęs a bucam┼▒velet a XVIII. sz├ízadban. Adatok a k├Âzvetlen elj├ír├ís t├Ârt├ęnet├ęhez Magyarorsz├ígon. Magyar Tudom├ínyos Akad├ęmia M┼▒szaki Oszt├íly├ínak K├Âzlem├ęnyei, 1963, Volume 32, 423 ÔÇô 447.

R├ęti, R. L├íszl├│ 1977. A Rimamur├íny-Salg├│tarj├íni Vasm┼▒ R├ęszv├ęnyt├írsas├íg t├Ârt├ęnete 1881ÔÇô 1919. Budapest, Akad├ęmiai Kiad├│.

Sarlay, Soma 1933. A Sturman-csal├íd eredete. Turul, 1933, Vol. 47, Nos. 1ÔÇô2, 35ÔÇô36.

Sarusi Kiss, B├ęla 1997. Vasgy├írt├ís ├ęs vasgazd├ílkod├ís Mur├ínyban a XVI. sz├ízadban. Fons, 1997, Volume 4, Issue 1, 79ÔÇô98.

Sashegyi, Oszk├ír 1969. B├ínyapolg├írok a forradalomban. Az 1848. ├ęvi orsz├ígos b├íny├íszati ├ęrtekezlet jegyz┼Ĺk├Ânyve. Lev├ęlt├íri K├Âzlem├ęnyek, 1969, Volume 40, Issue 2, 325ÔÇô 352.

Steier, Lajos 1937. A t├│t nemzetis├ęgi k├ęrd├ęs 1848ÔÇô49-ben. Budapest, Kiadja a Magyar T├Ârt├ęnelmi T├írsulat.

Szigetv├íri, Istv├ín 1962. Iratok a Rimamur├íny-Salg├│tarj├ín Vasm┼▒ Rt. lev├ęlt├ír├íb├│l az 1848ÔÇô 1849. ├ęvi szabads├ígharc hadianyaggy├írt├ís├ínak t├Ârt├ęnet├ęhez. Lev├ęlt├íri K├Âzlem ├ę nyek, 1962, Volume 33, Issue 1, 285ÔÇô310.

Szil├ígyi, G├íbor 1960. Iratok a Rimamur├íny-Salg├│tarj├íni Vasm┼▒ ├╝zemi bizotts├ígainak t├Ârt├ęnet├ęhez 1945ÔÇô1946-ban. Lev├ęlt├íri K├Âzlem├ęnyek, 1960, Volume 31, Issue 1, 285ÔÇô310.

Tahy, Istv├ín 1904. Tahyak ├ęs azokkal rokon csal├ídok. Budapest, P├ítria Irodalmi V├íllalat ├ęs Nyomdai R├ęszv├ęny-t├írsas├íg nyom├ísa.

V├ílyi, Andr├ís 1799. Magyarorsz├íg le├şr├ísa. Vol. 3. Buda, A kir├ílyi universit├ísnak bet┼▒ivel.

Vass, Tibor 1977. Jelbesz├ęd az ├ôzdi Finomhengerm┼▒ben. Miskolc, Hermann Ott├│ M├║zeum.

Volny, J├│zsef 2003. G├Âm├Âr megye b├ínyaipara (1867). Rudab├ínya, ├ërc- ├ęs ├üsv├ínyb├íny├íszati M├║zeum.

Veres, Szil├írda 1922. Eml├ękeim 1847ÔÇô1917. Budapest, L├ęgr├ídy testv├ęrek kiad├ísa.

Ung├ír, L├íszl├│ 1936. Magyarorsz├íg p├ęnz├╝gyei 1848ÔÇô1849-ben. Sz├ízadok, 1936, Volume 70, Issue 1ÔÇô3, 598ÔÇô660.